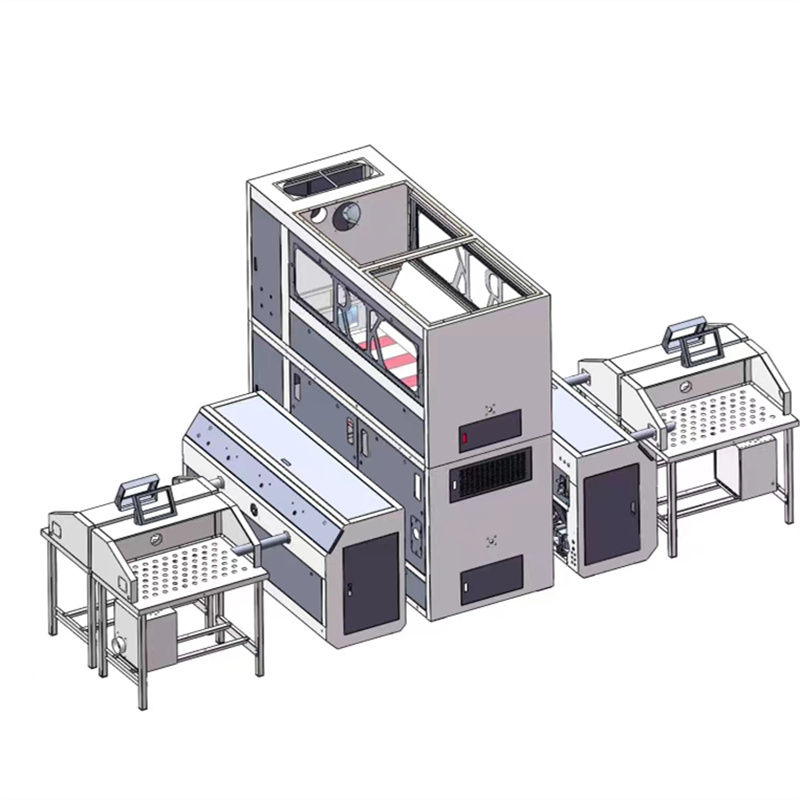

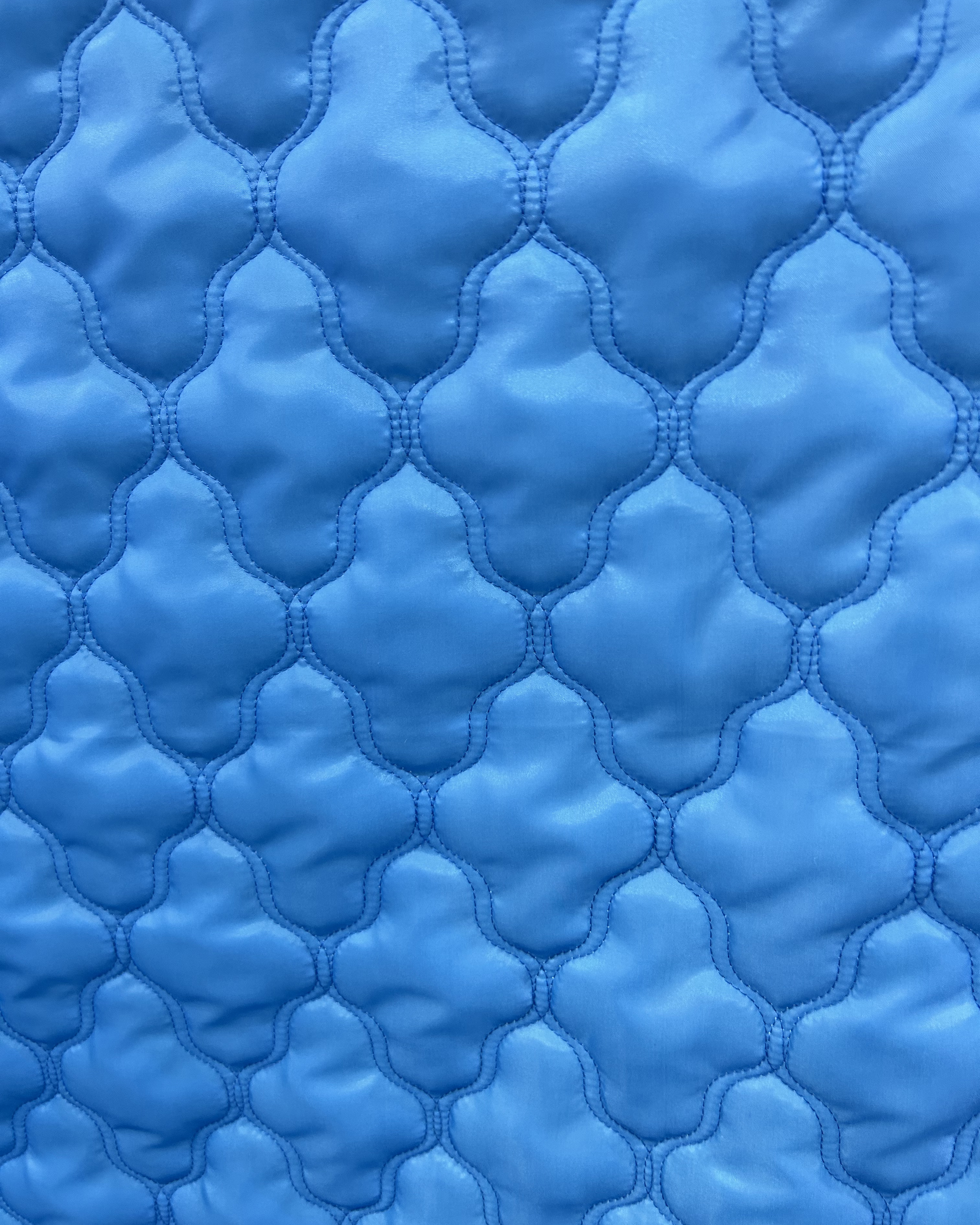

Plaub-axis linkage high-speed computer quilting tshuab

Lub tshuab no yog qhov tseeb hauv kev ua lag luam, nrog plaub-axis linkage high-speed quilting tshuab, ceev quilting ceev, tsis tshua muaj suab nrov thiab qis patch qaum tus nqi.

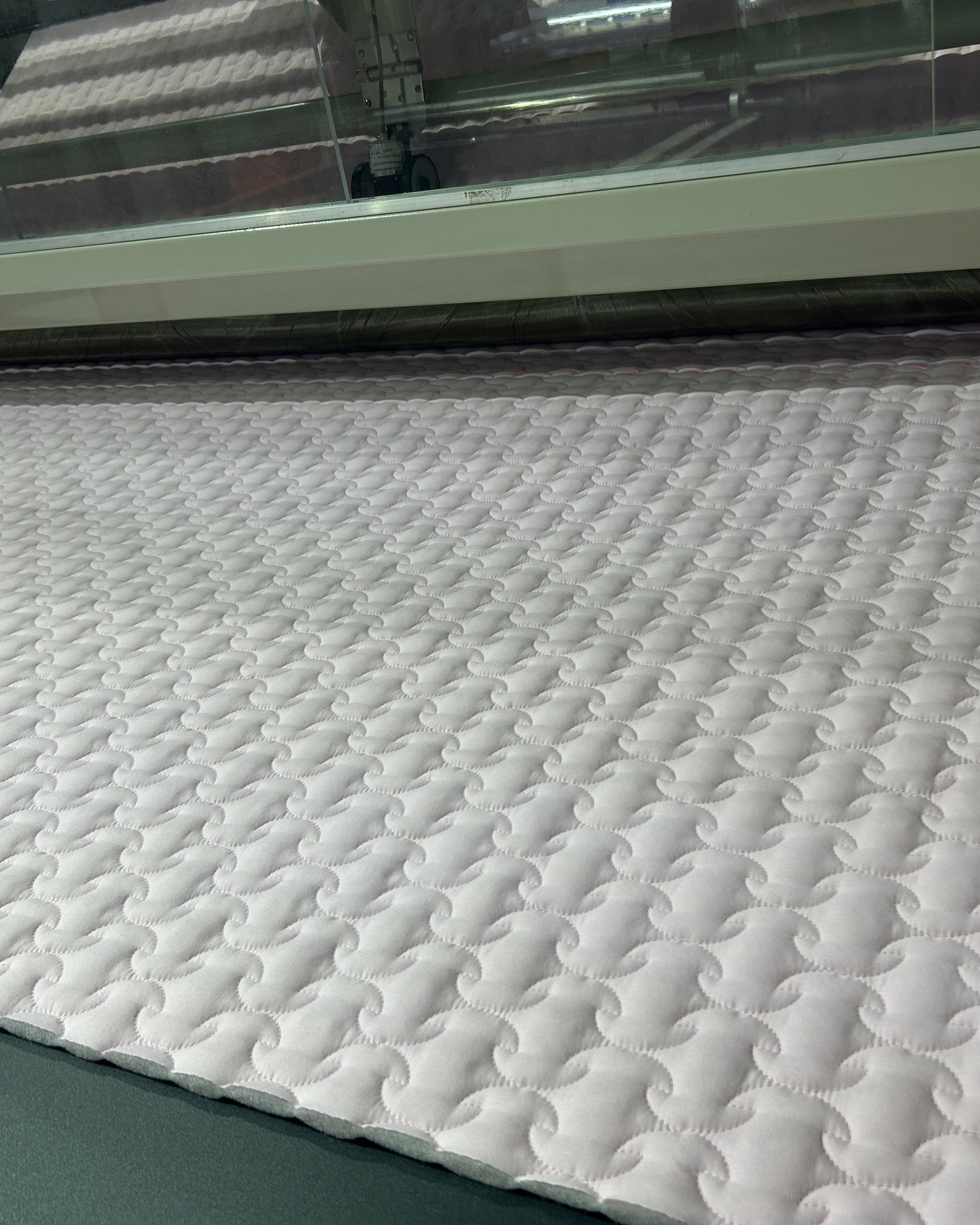

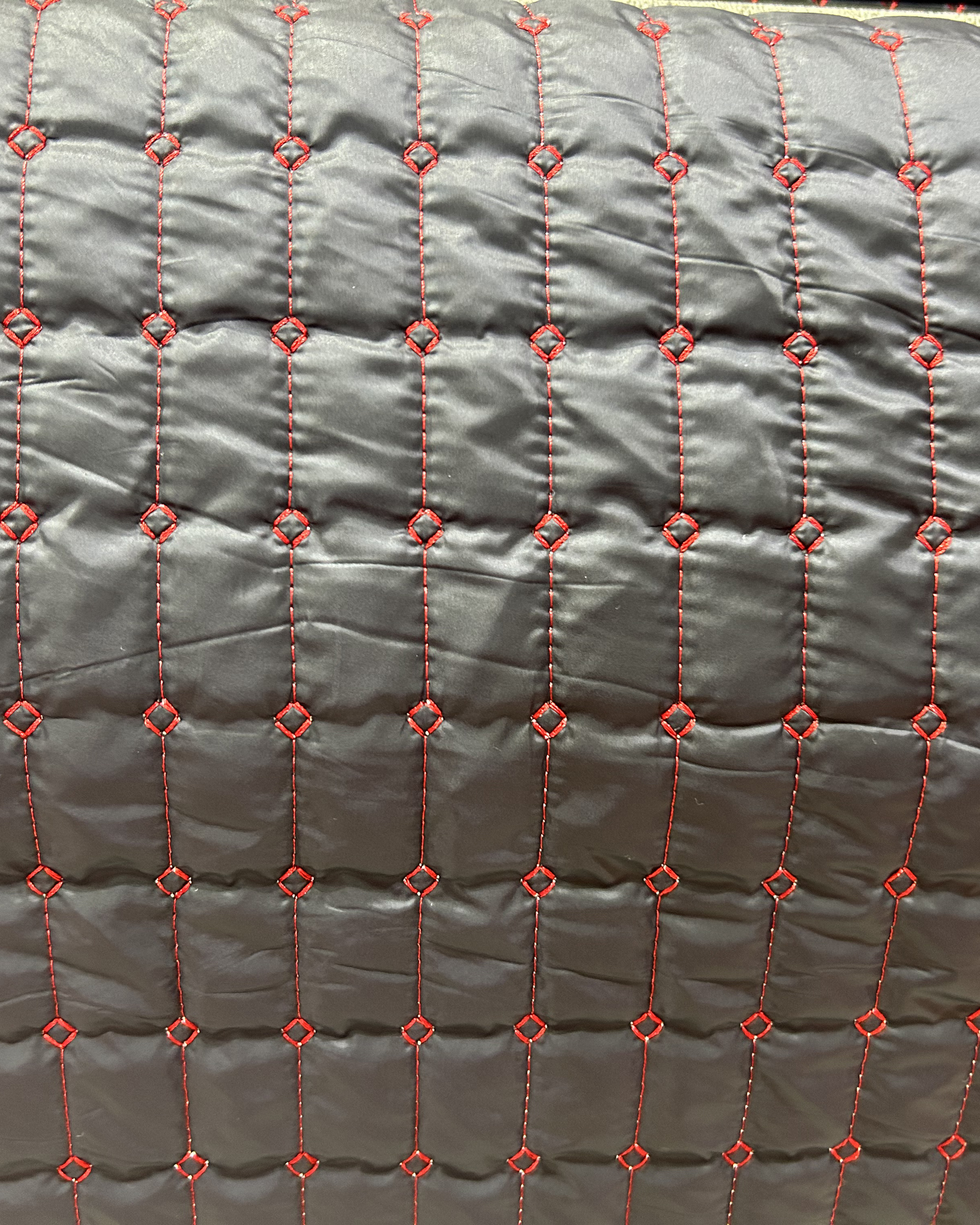

Daim ntawv thov:

Muaj nuj nqi

Khoos phis tawj multi-pin high-speed shuttle tshuab muaj nuj nqi / Function:

1.Advanced computer tswj thiab mechanical manufacturing technology, ywj siab hluav taws xob txee tswj, zoo tiv thaiv plua plav thiab kev puas tsuaj rau lub computer los ntawm kev co.

2.Qhov kev txav ntawm rab koob kab siab phaj txais yuav synchronous siv kis tsis tau lub log eccentric, uas txo cov kev vibration ntawm lub tshuab, nrog ceev ceev thiab qis suab nrov.

3.Lub koob tuav mechanism yog firmer thiab tsis yooj yim rau puas. Nws yog ruaj thiab tsis xav tau ntxiv refueling, yog li tsis txhob greasy fabrics.

4.Ob lub eeb ncej thiab cov menyuam txais servo tsav.

5.Lub ntsiab ncej adopts zaus conversion tswj ntaus ntawv.

6.Computer ceev tswj, koob ceev tuaj yeem ncav cuag 1000 koob / feeb, koob nrug 2mm-6mm txhua qhov chaw.

7.Ntau lub sij hawm hla-quilting (nrog 360 ℃ thiab 180 ℃ quilting qauv)

8.Advanced thiab cov tswv yim tshawb nrhiav tshuab ntawm kev sib txuas ntawm kab kab thiab tsis siv neeg kaw kev ua haujlwm ntawm kev sib txuas.

9.Qhov kev xav ntawm tes yog nyob ze rau ntawm lub sensor infrared, ua rau koj txoj haujlwm muaj kev nyab xeeb dua.

10.CAD txoj kev kos duab, duab kos, yooj yim thiab ceev.

11.Kuaj xyuas thiab qhia txog cov xwm txheej khiav ntawm lub tshuab.

12.Motor: spindle, X thiab Y servo motors yog tag nrho cov Japanese Panasonic hom.

13.Lub inverter yog ib hom Japanese Panasonic.

14.Linear qhia rail thiab cov menyuam pob ntsia hlau pas nrig yog Taiwan Shangyin hom.

15.Bearing: Nyiv

16.Machine koob: Grotz, Lub teb chaws Yelemees

17.Cov menyuam siv 45 # seamless steel yeeb nkab. Tom qab ua tiav, qhov saum npoo yog qhwv ib ncig ntawm daim kab xev tuaj txawv teb chaws, uas ua rau siv qhov tseeb ntawm cov qauv quilting thiab nto ntawm cov ntaub ntawv puas.

18.Cov khoom siv sib cais cov qauv siv cov kab ntawv qhia kev tsheb ciav hlau kom txo tau lub nra ntawm eeb ncej.

19.Lub hauv qab square pas nrig, koob kab yog imported los ntawm Nyiv Lub teeb tiaj tus, ruaj.

20.Noob phaj thiab siab phaj txais 304 stainless hlau phaj. Durable thiab tsis yooj yim rau disconnect.

21.Needle bar khib thiab siab bar rack txais aluminium alloy.

Tsis muaj

| (Unit mm) | TSY-94-2G/3G | TSY-96-2G/3G |

| Dimension (LxWxH): | 4380x1200x1700 | 4600x1200x1700 |

| Quilting dav: | 2450 | 2500 |

| Qhov chaw nruab nrab ntawm koob kab: | 76.2/152.4 | 76.2/152.4 |

| Qhov chaw nruab nrab ntawm koob: | 25.4 ib | 25.4 ib |

| X-axis txav txav: | 305 | 305 |

| Thickness ntawm quilting: | ≤ 20 | ≤ 20 |

| Stitch ntev: | 2 ~ 8 | 2 ~ 10 |

| Ceev ntawm ntau lawm: | 20-180 (m / teev) | 20-180 (m / teev) |

| Qauv ntawm koob: | 16# 19# nr. | 16# 19# nr. |

| Ceev ntawm lub ntsiab shalt: | 1000 (RPM) | 1000 (RPM) |

| Tag nrho lub zog xav tau: | 3.5 kwm | 6 kws |

| Voltage: | 380V 50HZ, 220V / 60HZ | 380V 50HZ, 220V / 60HZ |

| Qhov hnyav tag nrho: | 4500kg ib | 5000 kg |

Lus Cim: Yog tias koj xaiv qhov tshwj xeeb quilting muaj nuj nqi uas muaj ob-txheej txheem tsa

pom cov nyhuv, lossis xaiv 10 # bobbin, thov kom nws ua.